Maximizing Value of Your System

A Strategic Climb from Maintenance to Replacement

It is a truism that change is going to happen, and businesses will continually strive to grow. Growth can mean a lot of things; it doesn’t always mean building something new.

Many warehouse operations teams are asking: What can we build? How do we get more from what we already have? What do we do now? What do we do later?

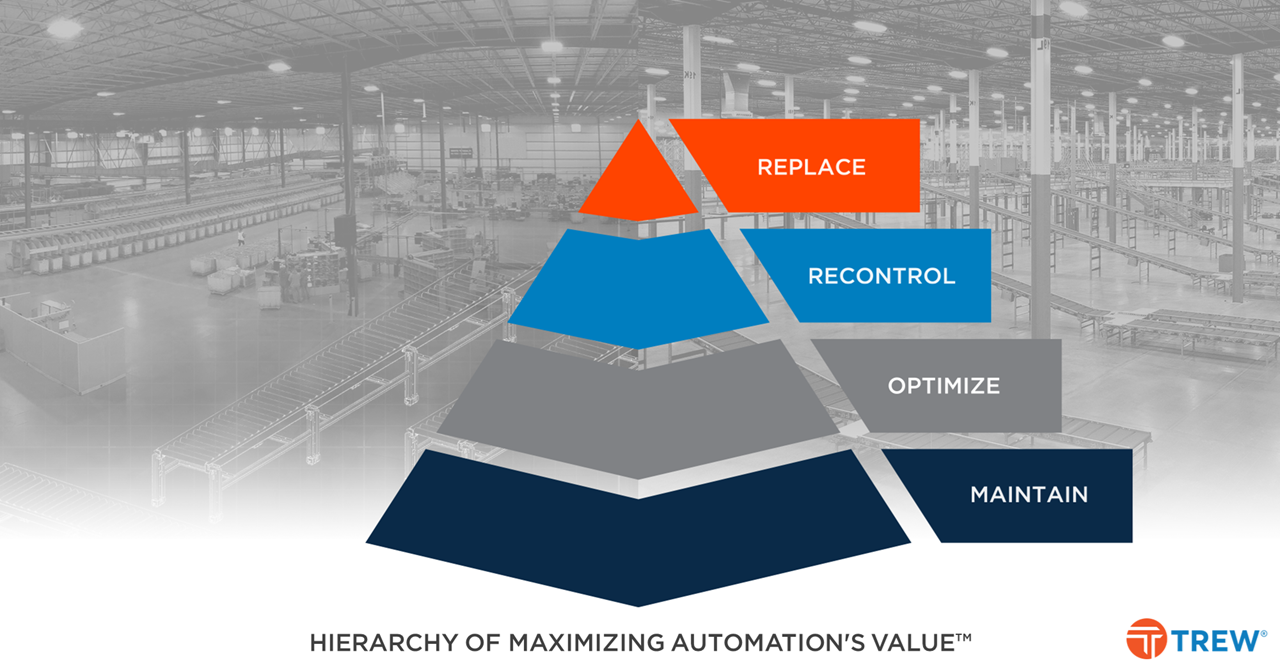

This blog discusses the options in a loose analogy to moving up Maslow's Hierarchy of Needs.

“The word of the times is certainly uncertainty.” [Trew]

In STIQ’s most recent Systems Integrators report they say, “Interviews [end users and integrators] suggest the word explaining the current situation is ‘uncertainty’ (alongside a few 4-letter words competing for top spot).” Was that risk, cost, debt, or something else?

The latest Logistics Managers’ Index (LMI) echoes that sentiment, citing stockpiled inventories and a murky trade policy outlook as the big question marks facing the U.S. market. Complicating things, costs remain high, and it is increasingly expensive for businesses to train and retain warehouse and logistics employees.

All of this uncertainty has logistics business leaders less sure than a Midwest sports fan convincing themselves this is finally their year to go all the way. (We say it every year… and there is no doubt we'll keep saying it.)

That same blend of hope and hesitation rings true for warehouse teams. Hopeful for growth, but hesitant to make the wrong move. With so much in flux, many teams are pressing pause on big investments and looking inward for alternatives and smarter ways to drive results.

When belt-tightening becomes a strategic initiative, the question shifts from “What can we buy?” to “How do we make the most of what we already have?” For fulfillment operations, that often means reassessing current systems, maintaining them, and improving them.

Do you move out or move up? How do you unlock efficiency gains and stretch your investment further? To help answer those questions, we’ve assembled four types of practical improvement strategies to help maximize the value of your automation investment.

A Strategic Climb from Maintenance to Replacement

-

Maintain & Assess - Prevent disruption by understanding what you have.

Start with the fundamental. Gain visibility into system health and lifecycle risk.

-

Obsolescence Planning helps you identify aging components before they cause downtime.

-

System Assessments provide a baseline for performance and upgrade readiness.

-

-

Optimize - Get more from what’s already in place.

Unlock hidden throughput, labor efficiency, and smarter orchestration.

-

Analyze Utilization vs. Capacity to improve system performance without new equipment.

-

Fine-tune Goods-to-Person picking strategies to align with demand and operational goals.

-

-

Recontrol - Modernize your OEM equipment.

Extend system life and gain visibility by upgrading controls and software.

-

Conveyor & Sorter Recontrols improve reliability and system integration of existing equipment.

-

Pick-to-Light software bridge breathes new life into aging order fulfillment hardware.

-

-

Replace & Expand - Invest in what’s next while staying in your current facility.

Make targeted upgrades that deliver long-term value within your existing footprint.

-

Accumulation Conveyor Replacement eliminates bottlenecks and improves system flow.

-

Brownfield Implementations introduce new automation where it fits best - no new building required.

-

New is a luxury that might not be in your immediate plans. Getting more from your current system might just be your best ROI play.

|

Thinking about building new? Don’t miss our blog on Brownfield vs. Greenfield Automated Solutions. It covers 7 key considerations to guide your Greenfield strategy. |

1. Maintain & Assess

Obsolescence Planning: Assessing Risk & Forecasting Updates

Unplanned downtime, unavailable parts, and unsupported tech can derail even the best-run operations. It can be easy to overlook scheduled maintenance until something blows up, but delaying updates can cost 3X more when accounting for hiring skilled labor, sourcing difficult replacement parts, and missed SLAs. Failure to act on obsolescence risks doesn’t just cause operational hiccups - you may be missing out on performance gains, simplified support, and the ability to scale quickly to meet new fulfillment needs.

Failure to act on obsolescence risks doesn’t just cause operational hiccups - you may be missing out on performance gains, simplified support, and the ability to scale quickly to meet new fulfillment needs.

Managing Risk

Understanding your Obsolescence Risk is the first step to managing costs and future-proofing your automation strategy. Measuring the probability and impact of negative outcomes due to aging infrastructure enables operations teams to create a beneficial lifecycle plan.

A few topics to keep in mind during this step include:

- Automation Equipment Age

- Legacy PC-based controls vs PLCs

- Software & OS Security

- Support Lifecycle

- Spare Parts

Planning Ahead

Supply chain leaders should consider several courses of action when developing an obsolescence plan:

- Conduct lifecycle assessments

- Develop phased transition strategies

- Build out spare parts and support contingencies

Read our Blog for more tips or use our calculator to Measure your Obsolescence Risk.

System Assessments: What You Don’t Know Can Hurt Performance

Many facilities are operating past their optimal lifecycle or simply aren’t using automation to its full potential. Decreased system throughput is an obvious red flag that an automation system is no longer meeting operational needs. Other key indicators include a business’ inability to meet SLAs and rising Cost-Per-Piece.

Uncovering Hidden Inefficiencies

Disruptions and out of balance material flow are the most common culprits behind poor system performance. Throughput is often limited by one basic issue: the system just can’t go with the flow.

To pinpoint the problem, start by asking a few questions:

- How is work generated?

- How does it move through the system?

- How is it consumed?

Upstream processes surge and wane. Every time they surge, it can cause bottlenecks. How do you keep things running steady through every process? Look at how work is spread out on the floor. Where are the constraints? Merges and sorters are usual suspects. Often, the root cause is an original design that wasn’t built for today’s volume or complexity.

Process inefficiencies are another hidden cause of problems in a system that appears to be “fine”. Everything may seem to be moving along smoothly, but underneath, a slow induct to a unit sorter or a pause to sip a Slurpee between picks (no judgment) could be holding operators back. Are steps out of sequence? Is something physically in the way? A few small changes can unlock much higher performance.

Material Handling Equipment Assessments

MHE assets are the backbone of your operation, but even the best maintenance teams can’t always tell when performance starts to slip.

Identifying component-level issues before failure hits is critical. With 24x7 operations or during peak season downtime isn’t an option. An assessment can uncover unseen risks and help prioritize what needs attention now vs. later.

When to Consider a System Assessment

-

Before or after peak season

-

During network changes or capacity planning

-

When systems seem “fine” but results lag behind

What an Assessment Covers

-

Mechanical wear

-

Software obsolescence

-

Layout inefficiencies

-

Throughput misalignment

Key Deliverables

-

Objective system health review

-

Prioritized improvement recommendations

-

Support for internal business case development

2. Optimize

Utilization vs. Capacity: Getting the Throughput You Paid For

The first step to getting your money’s worth out of a system is to understand the difference between capacity and utilization. Capacity is the theoretical max, or the rate your MHE could do in perfect conditions. Utilization is what it’s actually doing in the real world.

.jpg?width=512&height=272&name=image%20(2).jpg)

Getting to rated throughput is harder than it looks. Many operations don’t know their true utilization or cannot measure performance against it. Digging in to understand asset utilization can tell you what you can achieve with the equipment you have.

Bottlenecks, software limitations, and sequencing issues often hide in plain sight. One area might be capable of high rates, while another downstream or upstream can’t keep pace, creating imbalances that drag down the entire system.

Bridging the gap starts with visibility. Smart Warehouse Execution Software (WES) helps coordinate subsystems, adapt to exceptions (like if an area is full), and optimize flow across the warehouse. It acts like a conductor making sure the right orders, picks, and people arrive in sync.

Pro Tip: Don’t just measure orders out the door. Real-time analytics make it easier to react in the moment and continuously improve. Uncover hidden inefficiencies with metrics like:

-

Pick dwell time

-

Blockage events

-

Operator idle time

-

Zone-level throughput

Calculating Pick Rate in Goods-to-Person Automation: Look Past the Specs

In Goods-to-person (G2P) picking, mechanical rate is never your true pick rate. Just because a tote can be presented every three seconds doesn’t mean an operator can keep that pace. Real pick rate accounts for reaching, walking, scanning, and waiting on totes.

Some providers inflate throughput projections by factoring in order commonality across a full day’s worth of orders. For example, if the total SKU demand is 100 and 120 lines are picked, they assume a 20% commonality rate. In real operations, you’re not working with a full day’s worth of orders. You might only see three at a time. In that window, SKU commonality drops to zero.

To get a true read on performance, break pick data into realistic time slices. That’s where inflated assumptions fall apart, and where actual pick rate comes into focus.

If you’ve already invested in cutting-edge automation, you deserve to get the rate you paid for.

|

Read our blog to learn more: The Scoop on G2P Pick Rates |

⇑ Go to Top |

3. Recontrol

Conveyor & Sorter Recontrols: Breathing New Life into Legacy Systems

Recontrols are a cost-effective way to modernize aging warehouse systems without replacing mechanical infrastructure. When controls and software reach end-of-life, recontrols can restore performance, extend equipment life, and position operations for future growth.

Many facilities still run on outdated, PC-based control platforms that are difficult to support. Upgrading to modern PLC-based systems improves reliability, standardization, and long-term serviceability. Even better - recontrols allow you to unify legacy and modern equipment under a single software and controls platform, making it easier to maintain, troubleshoot, and scale over time.

Software Gets an Update

Open-platform HMI tools, like Ignition® HMI, can be layered over legacy systems to provide real-time visibility across your entire operation. With one interface, teams gain access to system health, alarms, and performance metrics without being locked into proprietary vendor software.

Recontrols also open the door to integration with next-generation Warehouse Execution Systems (WES). A modern WES enhances orchestration, smart routing, and system-wide efficiency, especially when it can connect to a broad mix of OEM equipment and new robotics technologies.

Whether you’re looking to extend asset life, reduce support complexity, or prepare for the next phase of automation, recontrols offer a smart path forward without completely replacing OEM equipment.

Helpful information for understanding risk and supportability of your

current software and controls systems: Controls & Software Assessments

Pick-to-Light Recontrols: Phased Out, Not Left in the Dark

As legacy pick-to-light (PTL) systems reach end-of-life, many operations are left with limited options. Support is fading, spare parts are harder to source, and software platforms are being sunset without clear upgrade paths. A full PTL system replacement is costly and not always necessary.

An Alternative Approach

An alternative approach is to recontrol what’s already in place - By adding a lightweight communication bridge between your WMS or WES and the existing PTL hardware, it’s possible to extend the life of your system without disrupting daily operations. These bridges act as translators - receiving picking instructions, triggering lights, and capturing acknowledgments - keeping core workflows intact.

Why it Works

This strategy works well with legacy systems from providers like Reddwerks, ATOP, Honeywell, and Lightning Pick. It allows teams to restore functionality, improve reliability, and gradually transition components over time - starting with software, then phasing in hardware as needed.

The ability to update one bay at a time or complete a partial replacement while the system is still running prevents businesses from falling behind. For many operations, this approach buys valuable time. It supports continuity today while enabling a planned transition to future technologies on a schedule that aligns with business needs and budget cycles.

|

Legacy pick-to-light systems may be fading out, but that doesn’t mean you have to stumble through the dark. Whether you’re dealing with unsupported software, aging hardware, or disappearing vendor support, there’s a smarter way forward. Learn more: Pick-to-Light Recontrols |

⇑ Go to Top |

4. Replace & Expand

Accumulation Conveyor Replacement: Unclog the Flow

Many accumulation systems still in use today were designed decades ago, and it shows. Older conveyor systems are prone to jams, crushed cases, and high maintenance costs. Their inability to adapt to modern variable flow rates makes them a growing liability.

If you see frequent downtime, damaged products, or rising service costs, it might be time to replace, not repair. Telltale signs include side-by-sides, product pileups, and increasing part failures. As lifecycle managers and maintenance teams know, some of these issues can’t be fixed, they’re symptoms of systems are past their prime.

Modern alternatives like motor-driven roller (MDR) and zero-pressure accumulation offer major gains. They’re quieter, energy efficient, and far easier to maintain. Intelligent zone control improves material handling and manual interventions boost merge efficiency, helping facilities get more throughput without more labor. Plus, new systems offer visibility and diagnostics that help operations and maintenance stay ahead of issues before they cause downtime.

These upgrades don’t have to be all or nothing. Phased replacements are possible - starting with critical areas like merges or palletizer feeds - allowing teams to minimize disruption while still moving forward.

Replacing outdated accumulation doesn’t just reduce maintenance. It improves flow, protects product, and lifts service levels across your operation. For many, that’s a win worth investing in.

Top 8 Signs It’s Time to Replace Your Accumulation Conveyor

-

Frequent jams or product backups

-

Crushed or side-by-side containers

-

Air leaks when the system is off

-

Product stalling in dead zones

-

Visibly worn hex axle holes in the side frame

-

Rising maintenance costs or part availability issues

-

Increasing downtime or missed shipping windows

-

Throughput not keeping up with order volume

Brownfield Implementations: Making the Most of the Space You Already Have

Automation doesn’t always start from scratch. In fact, many don’t have that option. For operations working within an existing facility, the challenge is clear: How do you modernize without disrupting what is already working?

Legacy buildings often come with oddly shaped spaces, uneven floors, or older infrastructure. That doesn’t mean automation can’t evolve. It just means you have to plan smarter.

The first step is mapping your current operations and identifying friction points. Where are the slowdowns? What workflows rely too heavily on manual labor? What processes break down under pressure? Once you’ve got a clear picture, you can begin shaping an automation strategy tailored to your business goals whether that’s improving throughput, reducing labor dependency, or increasing order accuracy.

In Brownfields, phased integration is critical. You can’t shut the building down; you need plans for cutovers and to work around live operations with surgical precision. Thoughtful planning and experienced project management of upgrades can make all the difference.

Robotics-Ready Retrofits

Planning to add AMRs, AGVs, or robotic order consolidation? Start with the basics:

-

Smooth, flat floors (older buildings often require remediation)

-

Power access and charging zones with sufficient amperage to charge robots

-

Dedicated lanes or corrals to keep robots away from foot and forklift traffic

-

Wi-Fi coverage strong enough to support navigation

-

Fire protection, lighting, and air flow to meet safety codes and insurance requirements

Sometimes the best path forward isn’t breaking new ground. Often times, operations are still able to get a lot of use from the space they already have with a few updates.

|

Read our blog to learn more: Brownfields vs Greenfields |

⇑ Go to Top |

Conclusion: Maximize the Value, Minimize the Disruption

Every warehouse has hidden potential whether through better orchestration, smarter upgrades, or strategic assessments.

In a world where every dollar counts, making the most of your current automation isn’t just clever, it’s essential. Whether it’s recontroling unsupported tech, squeezing more throughput from your existing footprint, or finally fixing that accumulation zone everyone side-eyes, creating value doesn’t have to mean new. It can mean smarter.

* Ignition® HMI is a registered trademark of Inductive Automation, Trew is an IA integrator partner

Investigating your options? We can help.Trew starts by listening to you and then uses a data-driven, collaborative solution development approach to define solutions tailored to your business strategy, financial objectives, and operational goals. Great solutions are a combination of people, processes, technology, and the software that pulls it all together. Explore more ideas to Maximize the Value of Your Automation Investment: |

.jpg?width=512&height=341&name=IMG_9993%20(2).jpg)