7 Considerations for Returns Automation

Let’s face it. The past two-three years have been atypical. The pandemic forced retailers to react to the environment and adapt. Was it easy? No. A crystal ball sure could have come in handy. The rise in e-commerce during the pandemic forced all retailers to re-examine and adjust their plans to deal with issues in the present. One such lingering issue is returns and how to deal with them.

Returns are no longer that small cost center located in the back of the distribution center. The statistics, when it comes down to dollars, are staggering. A few statistics to note that clearly depicts why retailers are choosing to address the returns situation:

-

Retailers expect more than $761 billion in merchandise sold last year to be returned. This accounts for 16.6% of total U.S. retail sales and is up from 10.6% during 2020.

-

Online returns in 2021 were higher: a whopping 20.8%, or approximately $218 billion of online purchases, were returned.

-

It is estimated that a $50 returned item will cost an average of $33, or 66% of its price, to process, up from 59% in 2020.

With stats like these, it is easy to see why retailers are looking to automation for returns. Depending on the retail category, as much as 80% to 95% of returned merchandise is resaleable, so finding ways to process returns in the most efficient and economical manner truly affects retailers’ bottom line.

When considering automation to provide a returns solution, retailers need to consider the following 7 characteristics of their operations:

-

“Time to pickable inventory”

Customers want their refund as soon as they drop off the item at the carrier. With so much of the product being saleable, the retailer needs to get the return processed and the product into a location within the facility where the product can be used to satisfy a new order. This is especially important with seasonal items or fast fashion that has a distinct window to command the highest price.

-

Packaging of the returned item

Packages arrive in all types of containers and conditions. Regardless of packaging, the returns process needs to be able to unload it from the trailer and get it moved through the processes of identification, inspection, and dispositioning, regardless of how it is packed.

-

Dispositioning

Now that the product is back in possession, what will you do with it? Dispositioning is a multi-step process that requires tiers of sort and segregation. Options include return to inventory, repair, return to vendor, vendor hold/RMA, send to reseller, recycle, or destroy - all with the goal for the fewest number of touches and focus on optimization of profit.

-

Peaks and Seasonality

The seasonality peaks that occur with holiday shopping trends as well as the intermittent volume spikes that occur at the end of promotions and product seasons can lead to a deluge in returns. Retailers need to make sure their solution is scalable to handle returns at their lowest and highest levels.

-

Space in the DC

When the DC was designed, an area for returns may not have been accounted for, at least at the volume that retailers are currently seeing. Minimizing the footprint of returns in the facility by quickly turning RTV “transitional” inventory and utilizing storage like CASRS and high bay racking may be necessary.

-

Labor

The labor shortage is not going away. Automation needs to reduce the dependency on labor. Just like everyone else in the retail industry, returns centers are struggling to find labor.

-

Total cost per piece

Returns are a cost center. We’re seeing more retailers just telling customers to keep their purchases while still providing credit because the cost to return the item is more than their current cost to process it. This can hurt your brand and set a negative customer expectation – and set up the possibility for abuse. The objective is to reduce the cost of returns and recapture as much profit margin as possible.

While automation will help, there is no one-size-fits-all returns solution. A data-driven approach by an experienced systems integrator who examines the items outlined above, as well as other data points, is the only way to determine the appropriate returns solution for any specific retailer. Manual touches are likely required for the item disposition, but most of the other processes for products within a sizeable range of form factors can be automated and coordinated with a retailer's RMS (Returns Management Software).

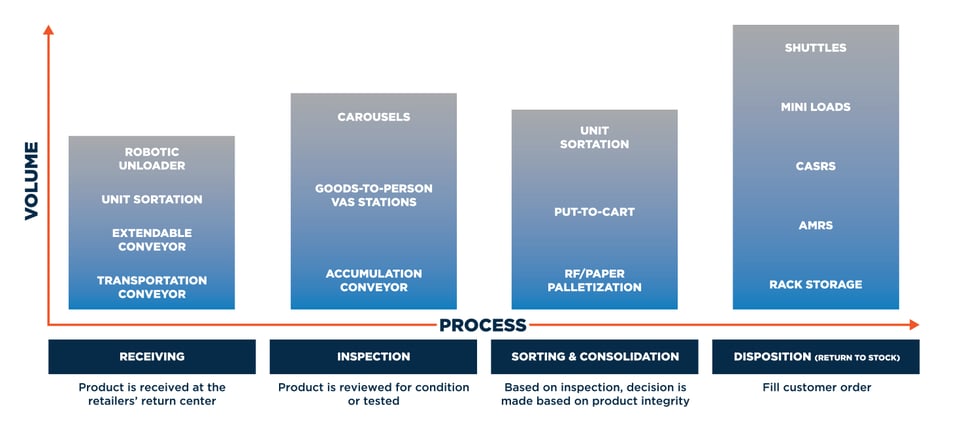

So, what type of automation technology is in use for reverse logistics? The following chart depicts a sample of the automation and considerations for the returns process by function.

Providing a returns solution that takes into account these characteristics, as well as ROI projections, will help determine the product mix of software, hardware, and manual labor required for a reverse logistics operation.

Examples of Reverse Logistics Operations

With the economy forecasted to dip into a recession, that crystal ball would still be of use, but returns will remain at the forefront as a challenge that retailers will need to mitigate to increase profitability. Retailers can work with systems integrators to take into account their unique challenges and develop a solution with remarkable ROI.

References:

- Inman January 25, Danielle, et al. “Retail Returns Increased to $761 Billion in 2021 as a Result of Overall Sales Growth.” Retail Returns Increased to $761 Billion in 2021 as a Result of Overall Sales Growth, National Retail Federation, 25 Jan. 2022, https://nrf.com/media-center/press-releases/retail-returns-increased-761-billion-2021-result-overall-sales-growth.

- Garland, Max. “UPS to Handle Record 60m Returns during Peak Shipping Season.” UPS to Handle Record 60M Returns during Peak Shipping Season, SupplyChainDive, 7 Jan. 2022, https://www.supplychaindive.com/news/ups-handle-60-million-returns-holiday-shipping-retail/616686/.

If you like this blog post, click here for the second installment of Trew's 3-Part Returns Series,

Solving Returns with Automation: The Goldilocks Dilemma.