Product Spotlight - Full Width Belted Conveyor

In today’s highly competitive e-commerce market, flexibility and efficiency are king. With packing labor typically 10% to 12% of the total labor within a fulfillment operation and shipping costs ranging between 5% and 15% of gross sales, the ability to pack orders as quickly and efficiently as possible is a must.

Fulfillment centers are implementing more packaging automation and generating a wider variety of packaging materials and sizes. Shippers are often padded jiffy mailers, poly bags, sleeves, and fit-to-size packages that are oddly shaped with a wide range of dimensions.

These challenges and more can easily be addressed with our 24VDC full width belted MDR conveyor. The Series 1500 full width belt conveyor maintains product orientation, consistently tracks packages with a focus on throughput, safety, and energy efficiency across the entire system. The belted zones provide zero pressure accumulation that can be used with product buffers with one product per zone to reduced damage to packages.

Hilmot’s 24VDC full-width belt MDR utilizes split zone sizes for our 24”, 30”, and 36” zoned conveyor, which amount to offerings of 12”, 15”, and 18” zones. This split zone capability helps convey smaller products such as poly bags, mail pouches, clothes bags, and small boxes often seen in e-commerce. The smaller zone sizes double the amount of accumulation and increase throughput across your warehouse. The additional accumulation capacity not only delivers higher rates, it can reduce your overall system investment by reducing the amount of conveyer needed.

Our 24VDC full width belted MDR conveyor is easy to maintain with TREW tracking, meaning it is continually and consistently moving straight. Utilizing a built-in tracking bead (located underneath the belt) gives superior tracking of the belt extending its life and reducing maintenance needs.

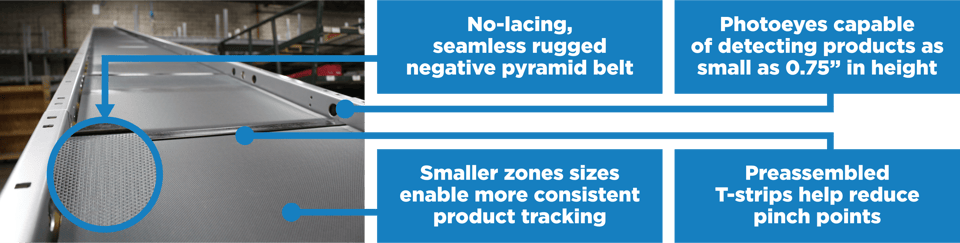

Utilizing a seamless (no lacing), yet rugged negative pyramid belt design helps keep product in place, especially for our incline and decline conveyor modules. Each zone is designed with a one-way bearing roller that has built-in anti-rollback - a mechanical brake that maintains accumulation and prevents product slippage, even if the system loses power.

With safety always at the forefront, we have cut no corners. Our conveyor comes with preassembled standard t-strips and finger guards that reduce pinch points - protecting product and people.

Working with a system underutilized because of package type limitations? Does it need to handle jiffy mailers, poly bags and small packages? Does the outbound process have the flexibility needed to handle variability in volumes? Our conveyor solutions can help, review our cutsheets linked here, or fill out the form below.

|

|

|