Warehouse Operations Two-Point Conversion

January, the time for warehouse operations to make their two-point conversion.

The 2023 holidays are in the rearview mirror and warehouse operations have a moment to catch their breath and celebrate their accomplishments supporting US retail. With Black Friday store traffic up 1.5% and Cyber Monday digital sales up over 9.6% versus 2022 record sales lead off a business holiday season says Black Friday and Cyber Monday Record Sales (forbes.com). While a time-out is well deserved, the game isn’t over.

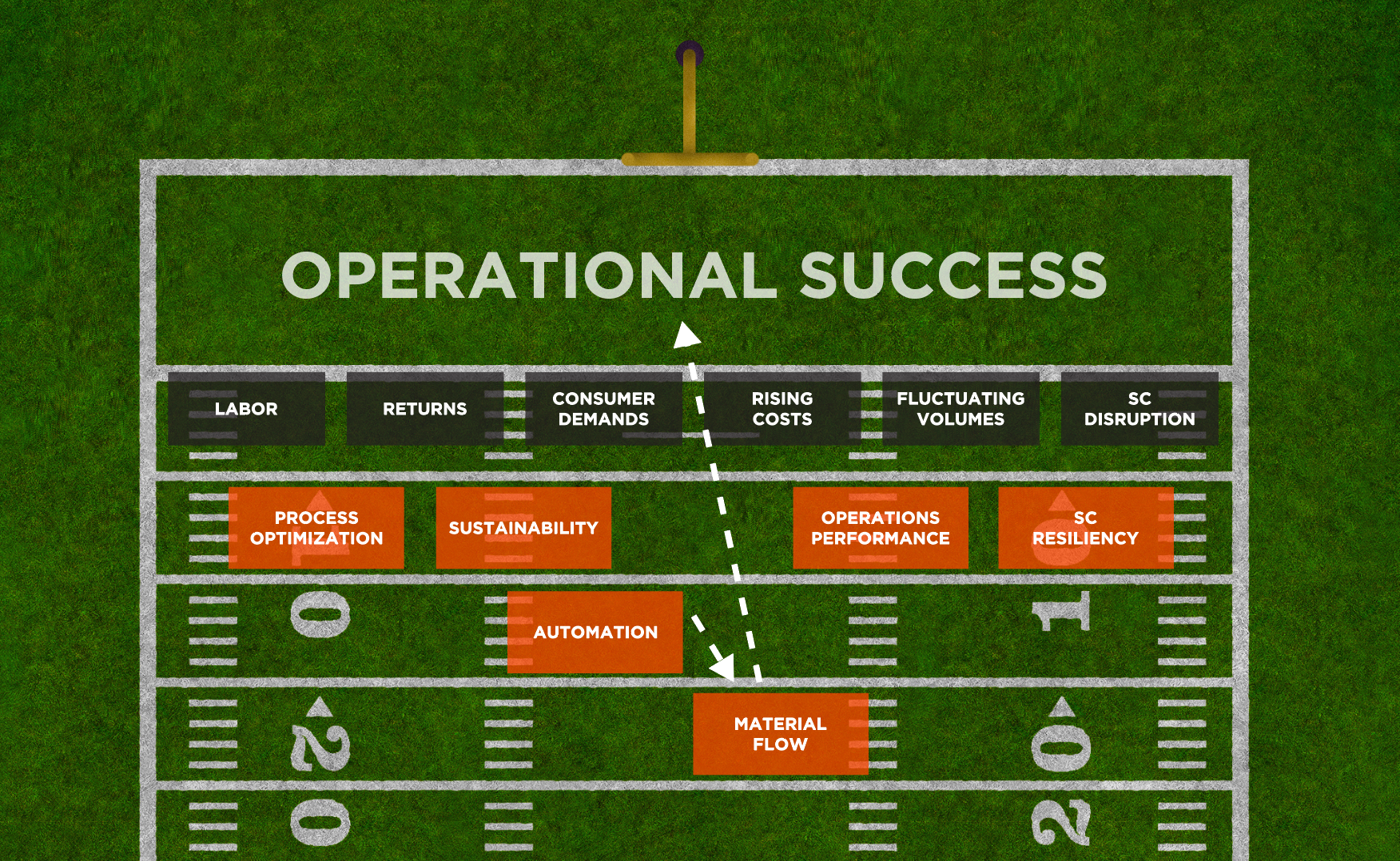

There are three reasons why warehouse operation’s leaders need to get their teams back into the huddle and prepare for what lies ahead of them in Q1 of 2024.

1. Gift Card Redemption - The gift card market is growing at a rate of 16.7% CAGR with 35% of them being redeemed within 45 days and 56% within 180 days says Essential Gift Card Statistics to Know in 2023 (moneyzine.com), with recipients typically spending an additional 20% or more of the gift card value says Gift cards can extend ROI into 2022 (usbank.com). As retailers take advantage of this with ad campaigns, promotions (Jan 20, 2024, is National Use Your Gift Card Day) and heavy discounts, a sizable amount of volume is injected back into the warehouse.

The order profiles change during this time with less commonality as consumers scoop up deals on remaining hot items and get started on next season’s merchandise (such as Valentines); and are incentivized by retailers to purchase heavily discounted aging SKUs, clearance, and items with historically low C & D velocities. Warehouse operators will need to look at reprofiling pick locations in their automated and manual systems to adjust pick zones to accommodate the changes, often comingling low on-hand inventories.

Inventory discrepancies become highlighted at this time of year, so it becomes important to expedite the exception handling process, leverage order suspension to prevent bottlenecks, and readdress stock-cut guidelines to balance service levels, labor costs, and inventory dollars.

Coming out of the holidays, storage is often left fragmented and needs tending. Consolidating locations and moving loads towards the inner perimeter of the operation will provide efficiency gains for end-of-season replenishments and open areas to expedite receiving stock for the next season.

2. Operating expenses are always at the forefront of every warehouse leader’s mind contending with escalating labor, energy, lease, consumable, and shipping costs. Look for hefty rate hikes in 2024, parcel consultants say (FreightWaves). Deep discounts used to move end-of-season merchandise means less margin on the table, so maintaining cost per piece is critical this time of year.

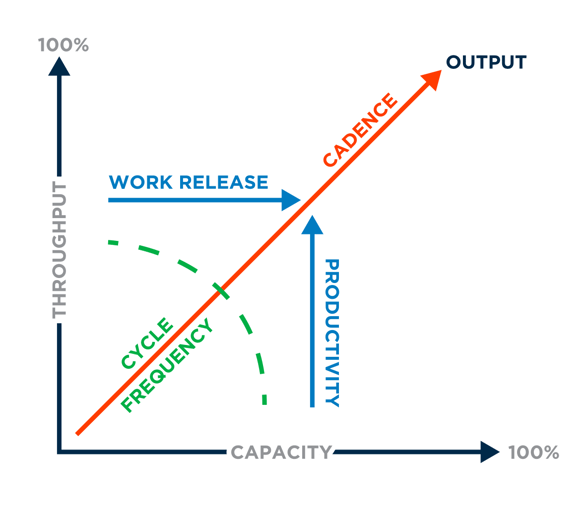

Just because the holidays are over, doesn’t mean the pressure goes away. In fact, it intensifies. Volume absorbs a lot of things, when it drops, it is even more important to maintain control of productivity and throughput targets, adjusting pick zones, right sizing staff levels, and setting aggressive cadences.

While the metrics of the recent peak seasonal information are fresh and readily available, January is the perfect time to begin assessing the business case for warehouse automation. The right automation can help operations by increasing productivity, reducing the dependency on labor, improving space utilization, and cutting packing waste. The objective is to exchange hard-to-control variable costs for fixed costs that produce higher throughput, sustainability, and resilience. January is a great time to start gathering data for this evaluation.

Material flow determines the success of any warehouse operation. Good flow with consistent origination and consumption yields high performance. January is a good time to evaluate warehouse material flow and bottlenecks to identify opportunities to optimize workstations and streamline processes.

3. Returns – Retail returns were expected to grow 2.2% in 2023. Retail Returns Will Surpass $620 Billion in 2023 (Insider Intelligence). Not all facilities deal with returns, but for those that do, they understand the Q1 challenges with returns, damages, overstock RTVs (return to vendor), and the complexity of the return’s operation to ensure items are processed cost effectively, timely and accurately so maximum product value is recaptured.

Perhaps the biggest challenge is identifying the SKU and validating the disposition. This is typically a laborious task that must stay in step with the flow of inbound returns. Setting up ergonomic stations that allow operators to focus solely on the validation process often justifies having dedicated teammates as runners bringing in new loads and taking away those that are completed.

Adequate staging buffers between the induction process and the process of disposition sorting is critical to keeping flow moving. Returns are never equally balanced per disposition so the operation must allow workstations to adjust and accommodate as per the demand.

Expedient processing of goods available to sell is critical to re-capturing sales opportunity and accurate financial reporting. Make sure that the return-to-stock processing is adequately staffed and the physical process of return to a “sellable” inventory location is simple. A way to minimize time and space usage is with a random putaway method that allows comingling and multiple locations per SKU.

Capturing salvageable, and resalable merchandise given today’s circular economy can provide a sizable and worthwhile return if done correctly. Rather than treating this category as a “catch all,” give it similar thought and process rigor as RTV and RTS.

The first quarter of each year is like a game in overtime, where the final play makes a difference between a win and a loss. The first quarter, as its name suggests, also serves as kick off to a new game for next year. It is a different game in the 3rd and 4th quarter when in the first half you put a lot of points on the board.

No matter how we look at it, following a touchdown with a two-point conversion play to win the championship game is a good thing in anyone’s playbook.

“If you sit back and spend too much time feeling good about what you did in the past,

you're going to come up short next time.” – Bill Belichick