Pick, Pack, Ship That Scales

Fast, flawless delivery is the name of the game when striving for ecommerce success. One late package can cost a customer, and a pattern of them will cost your brand. “On Time in Full” now means faster, cheaper, and more choices than ever before.

Tighter delivery promises and exploding product variety continue to strain even the strongest operations, while transportation costs and labor retention pile on more pressure. 42% of merchants surveyed by Retail Dive report that consumers’ growing delivery expectations have caused major disruptions for their operations, proving consumers are more impatient and more unforgiving than ever.

Startup darlings and retail giants alike must offer endless choices, near-instant delivery, and flawless execution or risk losing as many as 85% of online shoppers after just one bad experience.

Table of Contents

-

Trending Fulfillment Problems

-

The Solutions

-

Design for Scalability

-

Optimize Inventory

-

Smart Picking

-

Precision Packing

-

Streamlined Shipping

-

The Connective Tissue

-

Top 5 Time to Value Considerations

-

TREWPartner: Geek+

The Problems: SLAs, Labor, and Shrinking Margins

1. SLAs and Speed

According to a 2025 McKinsey & Company article, on-time delivery has never fully recovered from its pandemic dip. After hovering around 85–90% pre-2020, last-mile reliability plunged to 72% in May of that year and still hasn’t bounced back.

Consumer expectations for same-day or next-day shipping have reshaped how fulfillment teams operate. What used to be “fast enough” now puts brands behind before the day even starts.

Here’s the real kicker: For 3PLs shipping on behalf of someone else’s brand, missing those SLAs doesn’t just frustrate customers. It often comes with chargebacks, performance credits, and strained client relationships.

Automation provides the speed and consistency operations need to hit the SLAs they promise.

2. Transportation Costs

Transportation costs are rising, and it’s not just fuel driving the pressure. Carriers are stacking surcharges, dimensional weight rules punish oversized boxes, split shipments double last-mile costs, and hazmat or returns add their own handling fees.

While transportation is often the largest and least controllable cost bucket in fulfillment, small upstream decisions make big impacts downstream:

- Order Consolidation: Combining compatible orders into a single shipment maximizes cube utilization and reduces parcel counts.

- Right-Sized Packaging: Using cartonization logic and automated packaging equipment minimizes dimensional weight charges, material waste, and carrier penalties.

-

Print-and-Apply Labeling Systems: Automated labeling ensures retailers do not incur additional penalties for things like incorrect label placement, size, format, or missing regulatory information.

3. SKU Availability

Even the best order selectors can’t pick what isn’t there. Inventory visibility is critical, especially when you are dealing with 100,000s of SKUs. Gaps between what’s in the WMS and what’s on the floor create ripple effects: short picks, partial orders, and inaccurate inventory counts. Regular cycle counting, exception-based audits, and real-time replenishment triggers close that gap.

A warehouse execution system brings these practices together by completing accurate receiving and putaway, triggering replenishment before slots run dry, and escalating exceptions the moment they appear. When inventory truth is protected, picking stays fast, accurate, and predictable.

4. Labor Availability

Labor has become one of the most unstable parts of fulfillment. Turnover remains high. Technology can help, but the answer isn’t simply to “automate more.” The answer is to uncover hidden inefficiencies. That means giving new associates simplified tasks, guiding every picker along an efficient path, balancing work across zones, and reducing the cognitive load that drives errors and burnout.

5. Order Accuracy

Errors can hide in plain sight without clear synchronized data between inventory and order fulfillment or clear operator instructions.

A good warehouse execution system eliminates these blind spots by validating picks as they happen, synchronizing digital and physical inventory states, and enforcing verification through barcode scans, weight checks, or light confirmations.

The Solution: Pick, Pack, Ship That Scales

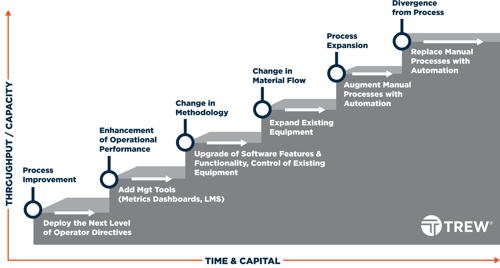

How do you approach making the best investments for your company? When enhancing and expanding warehouse and fulfillment operations, working through the range of possible process and technology options can be confusing.

At scale, fulfillment becomes a balancing act. As businesses grow, so do expectations. More products, more customers, and more shipping destinations add layers of complexity.

Technologies can solve problems of each fulfillment function, but modern problems demand creative solutions to match each stage of growth. As fulfillment operations scale, it is important to first investigate the systems in place and learn where processes need to be improved. From there, the appropriate pick, pack, ship automation can be fit into the overall solution to create the desired business results.

Design for scalability

Retailers can scale intelligently by layering improvements over time, starting with simple process upgrades and moving toward more advanced material flow automation as throughput, complexity, and capital evolve. Each step strengthens the operation and sets the stage for the next.

1. Process Improvement

Start by giving operators better tools and clearer guidance. Small changes here deliver fast ROI and reduce training overhead. A good first step is to deploy the next level of operator directives. Operations can achieve this by upgrading from paper picking to RF-or light-directed picking to provide clearer navigation to picks.

2. Enhancement of Operational Performance

Once core processes are stable, adding visibility and decision support empowers supervisors to manage proactively instead of reactively. Introducing management tools like metrics dashboards or real-time performance insights helps to identify where bottlenecks may occur and prevent them.

3. Change in Methodology

With higher order volume or SKU complexity, operations benefit from more intelligent software and tighter equipment control. Upgrading existing equipment control can include recontroling an aging sorter to operate on modern PLC controls to improve reliability, or introducing better orchestration between WMS level data and automation equipment with a WES that sequences picks and prioritizes case movements for consumption.

4. Change in Material Flow

As throughput needs increase material movement can become a bottleneck. Finding the most efficient route between processes and connecting equipment creates stable, predictable flow.

5. Process Expansion

Expanding fulfillment processes is the next logical step as capacity needs increase along with available capital. Automation starts taking over high-touch or repetitive tasks, allowing labor to focus on value-added work. Augment manual workflows with automation. This can look like adding AMRs to move materials between human operators in pick zones.

6. Divergence from the Original Process

Finally, mature operations can redesign workflows entirely, replacing manual steps with automated subsystems built for peak speed and efficiency. For instance, instead of humans picking manually from racks, a goods-to-person system delivers picks from automated storage directly to a workstation manned by a human or even a robotic arm, eliminating walk time and maximizing accuracy.

Now that we have reviewed the framework and high-level examples for enhancing fulfillment operations with process improvements and automation, let’s look at some specific tools to incrementally level-up pick, pack, and ship.

Optimize Inventory

Even before the fulfillment process starts, the inventory needs to be right. The goal is keeping counts correct and making sure product is positioned where it will be needed next.

-

Cycle Counts & Audits: Routine verification ensures data integrity, allowing real-time corrections instead of end-of-month surprises. These can be manual or automatically triggered by exceptions.

-

Replenishment: Automatic replen maintains forward pick zones based on velocity and demand forecasts, moving products from reserve storage to where they can be picked.

-

Cross-Docking: For fast-moving goods, the WES can identify inbound cases that should bypass storage entirely, label them, and move directly to outbound shipping.

-

Exception Management: When shortages occur, the system flags and isolates them immediately to a hospital area, preventing one error from disrupting the entire wave.

From an equipment perspective, optimizing inventory includes upgrading traditional warehouse racking to a mini-load shuttle or ASRS to take advantage of vertical space. These solutions can accommodate 100,000s of SKUs at high throughput rates. They can also be combined with pick stations for goods-to-person picking.

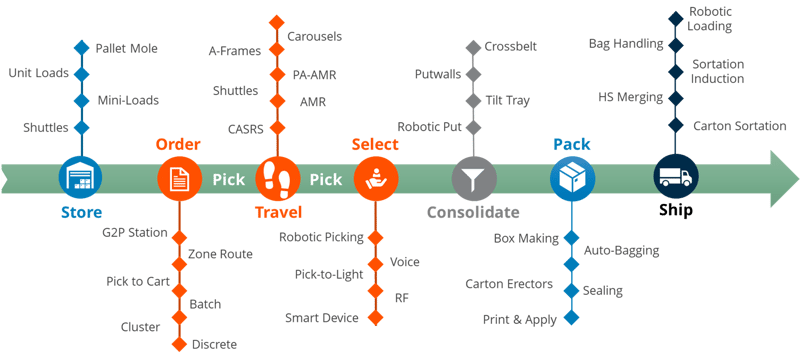

Smart Picking

Picking is one of the most labor-intensive and variable process in the warehouse, accounting for over 50% of labor cost! Picking methods and equipment can be mixed and matched to address various fulfillment challenges.

Picking Approaches

-

Batch Picking: Batches enable operators to pick multiple orders at once. A smart WES routes operators through optimal pick paths and assigns tasks based on experience level. New operators get smaller batches and required scans; experts get larger assignments without sacrificing accuracy. This reduces travel, speeds training, and keeps every aisle balanced.

-

Cart Picking: Operators build carts, associate totes, and follow RF-directed routes to pick multiple orders.

-

Quick Pick / Hot Pick: When an urgent or short item is identified, the WES dynamically releases a targeted task so operators can resolve it without holding up a full wave.

Equipment Options

1. RF- and Light-Directed Picking: When fulfillment operations evolve from using paper picking to incorporating RF picking, operators use handheld or wrist-mounted mobile devices connected to the facility’s Wi-Fi network to scan locations and/or items to confirm picks. RF workflows play a valuable role for operations with wide zones, pallet or case picking, C & D movers, or areas where data capture (lot, serial, weight) is critical.

In split-case, store replenishment, and high-density pick zones, pick-to-light (PTL) delivers speed and accuracy. Lights eliminate search time, reduce cognitive load, and enable multi-operator zones without confusion. RF typically improves pick rate by 10-15% over paper at a lower upfront hardware cost. As pick velocity and density increases, organizations may consider pick-to-light for a 30-50% productivity lift and minimal operator training time.

2. Autonomous Mobile Robots (AMRs): AMRs can serve as mobile pick carts, runners, or picking assistants. They’re a practical entry point for smaller or growing operations looking for incremental automation. Organizations can easily add or take away AMRs as needed, and in some cases they can replace fixed conveyor for added flexibility.

3. Goods-to-Person (GTP): Ideal for dense storage and high-velocity items, GTP systems deliver inventory to the operator, eliminating walking and increasing pick accuracy. Goods-to-person solutions can be categorized into four types

-

-

Module-Based – A self-contained subsystem that offers a great replacement for low-velocity pick modules. Multiple modules can be connected via conveyor to pass the orders to the modules where the SKU resides.

-

Aisle-Based – Consists of shuttles operating in designed aisles and levels within each aisle to retrieve totes or cartons from shelving. Good for higher order volumes and larger SKU populations.

-

Cube-Based – A dense grid stacked with bins that robots predominantly move on top of the grid and extend mechanisms to dig for the tote from the stack. Workstations are located on the perimeter of the grid structure.

-

Corral-Based GTP

Corral-Based GTP

“Corral” based goods-to-person systems typically consist of aisles with bins stored 1 to 3 positions deep. The robot can either be one that climbs the racks to access the bins, or it can be an AMR with a mast capable of inserting/extracting bins and then carrying them on its mast. The corral-based solutions take the principles of the “Cube” and introduce an additional layer of flexibility and accessibility.

Key Features:

Decoupled Processes: The workstations are not part of the ASRS, and they are not connected to the storage using conveyor.

Automation: This is where solutions within this category can differ. Robots may do the retrievals and transporting to the workstation or they may hand off the retrieved bin to another robot for the transporting.

Storage: Depending on the system, the storage gets closer to traditional racking with more typical fire suppression approaches.

Advantages:

Scalability: Corral-based systems connect multiple aisles providing for nearly infinite aisle capability, allowing for scalability and higher SKU capacities.

Mobility: Using robots to decouple the storage/retrieval from the bin transportation allows the system more flexibility to manage flows to workstations and reduce congestion.

Accessibility: Other than having 2 or 3 bins deep storage, these systems offer accessibility by any robot to retrieve any tote for any workstation.

Redundancy: Ensures high system uptime, as multiple robots can operate simultaneously within a single aisle or across multiple aisles.

Precision Packing

Precision Packing

Packing is where precision meets presentation. Packaging can be done at the order start or order finishing, before the order meets the customer. The standards here define brand perception and heavily influence transportation costs.

-

Packaging Automation: Carton formers, carton erectors, and automatic lidders keep pace with varying order sizes and reduce wasted space and packing materials.

-

Print and Apply Labeling: Layered verification of barcode and weight ensures that what’s packed matches what was labeled. The result: precise label placement and maximized savings on shipping costs.

-

Cartonization: As orders move through the warehouse, dimensional and weight data feed back into the system, refining packaging and shipping decisions.

Streamlined Shipping

In shipping, warehouse operations flow into the realities of carrier schedules, cube utilization, and transportation cost.

-

Routing & Sortation: Automated routing directs cartons to the correct carrier lane or trailer based on destination and cutoff times.

-

When engineered to match the building layout, items being handled, the rate required, how products are packaged, how they’re inducted, and how they exit the sorter, sortation becomes a powerful lever for capacity, accuracy, and overall fulfillment efficiency.

-

Today’s fast-paced e-commerce and retail fulfillment operations require sortation designed specifically for high-throughput, high-accuracy environments.

-

-

Rate Shopping: Integration with carrier APIs enables selection of the most cost-effective shipping option in real time.

-

Fluid Loading: Loading and unloading trucks is the most labor-exhaustive job in any fulfillment operation. Automatic loading eases the amount of stress and strain on both dock employees and packaged orders.

Connective Tissue

Connective Tissue

As volumes fluctuate, conveyor unites discrete pick, pack, ship processes. Sustained, high-rate performance comes from conveyor’s ability to hand off cartons continuously. We like to refer to conveyor as the connective tissue of the warehouse.

Along the way, it feeds pack-out automation like lidders, case sealers, and right-size packaging machines; it carries cartons through inline print-and-apply labelers, scales, and dimensioners to ensure accuracy and carrier compliance; and it drives shipping performance by diverting cartons to shipping lanes through high-rate sorters.

Accumulation conveyors absorb variability, regulate release, and prevent upstream and downstream volume mismatches from creating bottlenecks. They are the operational shock absorbers of automated distribution and fulfillment.

The Bottom Line

The true payoff of automation lies in how quickly your operation can climb the ramp to full performance. That means understanding every component of the proposed solution, from expected learning curves to how long it will take associates to reach projected productivity levels.

Treat ramp-up like its own workflow: track progression by process, use on-site testing time to build confident operators and emerging leaders, and put the right measurement tools in place to monitor throughput, productivity, and non-standard time in real time.

The faster your teams can generate and sustain flow in the new system, the faster you realize true value of your automation.

Top 5 Time to Value Considerations for Pick, Pack, Ship Automation

-

Ensure you understand each component of the proposed solutions, how long it will take associates to reach the projected productivities, and the estimated costs to be incurred within that period when your operation is not at the performance goal.

-

Track the ramp-up progress for each new process that is implemented.

-

Use on-site testing time to train associates and develop leaders.

-

Have the tools in place to accurately and timely measure throughput, operator productivity, and non-standard time.

-

Coach the operational team on how to generate and sustain material flow in the new system.

Finding the Right Solution

TREWpartner: Geek+

Autonomous Mobile Robots (AMRs) have become one of the most flexible tools in warehouse automation, bridging the gap between manual and fully automated systems. TREWpartners like Geek+ have shown how AMRs can be deployed quickly, scaled easily, and integrated across multiple workflows from tote-to-person picking to pallet-to-person fulfillment.

AMRs are also one of the most approachable forms of automation for facilities taking their first step. They require minimal infrastructure changes, offer rapid ROI, and can be layered into existing environments to complement human labor rather than replace it. It’s a perfect example of progressive automation: starting small, learning fast, and scaling strategically.

RoboShuttle™ Tote-to-Person Picking Solution

Engineered to optimize vertical space and performance, Geek+ RoboShuttle operates in warehouses up to 40’ high and can be integrated into brownfield operations for enhanced throughput and space optimization. The flexible solution combines the advantages of the two different robots: RS moves totes from storage rows for collection, and P40 carries the totes to a picking station. RoboShuttle is idea for complex whole container storage and picking, micro fulfillment, and small items.

| AMR Model | RS11-DX | RS11-DA | RS8-DA | P40 |

| Dimensions | L1800 × W1000 × H6200 (Max height 11075 mm) | L1800 × W1000 × H6200 (Max height 11075 mm) | L1800 × W1000 × H4700 (Max height 8245 mm) | L650 x W450 x H386 mm |

| Weight | 960 kg | 970 kg | 900 kg | 60 kg |

| Maximum Payload | 40 kg | 40 kg | 40 kg | 40 kg |

| Standard Container Dimensions | (400~650) x (400~450) x (280~500) mm | (300~650) x (300~450) x (150~500) mm | (200~650) x (200~450) x (150~400) mm | 400 x (300-600) x 400 mm |

| Maximum Speed | Empty 1.8m/s, Full load 1.2m/s | Empty 1.8m/s, Full load 1.2m/s | Empty 1.8m/s, Full Load 1.5m/s | Empty & Full Load 4.5m/s |

| Navigation | Inertial sensors + QR code | Inertial sensors + QR code | Inertial sensors + QR code | Inertial + QR code visual navigation |

| Run Time | Self-charges in 10 minutes, operates for 2 hours | Self-charges in 10 minutes, operates for 2 hours | Self-charges in 10 minutes, operates for 3 hours | Self-charges in 10 minutes, operates for 1~1.5 hours |

Swipe for more →

Shelf-to-Person Solution

Geek+ Shelf-to-Person uses picking robots to improve accuracy by transporting shelves holding inventory to a picking station - improving picking efficiency by 2-3X. Geek+ offers both single- and multi-layer shelf-to-person picking solutions. Primary features include:

-

Order optimization and wave picking

-

Heat mapping and placement recommendations

-

Inventory layout adjustment

-

Inventory management and intelligent tally

- RFID technology integration

| AMR Model | P500R | P800R | P1200R |

| Dimensions | L950 x W702 x H275 mm | L1095 x W830 x H195 mm | L1325 x W1020 x H275 mm |

| Weight | 144 kg | 142 kg | 288 kg |

| Maximum Payload | 600 kg (800 x 880 / 1020 x 1020 mm) | 1000 kg (1020 x 1020 / 1250 x 1250 mm) | 1200 kg (1250 x 1250 / 1600 x 1600 mm) |

| Maximum Lifting Height | 60 mm | 55 mm | 60 mm |

| Maximum Speed | 2m/s without load 1.5m/s full load | 2.3m/s without load 2m/s full load | 2.6m/s without load,2.2m/s full load |

| Navigation | Inertial sensors + QR code | Inertial sensors + QR code | Inertial sensors + QR code |

| Run Time | Self-charges in 10 minutes, operates for 1.5~2 hours | Self-charges in 10 minutes, operates for 1.5~2 hours | Self-charges in 10 minutes, operates for 1.5~2 hours |

Swipe for more →

Pick, Pack & Ship Automation

READY TO GET STARTED? LET'S TALK.

Please submit this form.