How Mobile Robotic Solutions Are Solving the Top 4 Fulfillment Challenges

Whether your operation is big or small, the challenges most likely keeping you up at night are:

-

Labor - Will you be able to attract, hire, and keep the talent needed to ship the necessary orders? How much will it cost to get the right people? How long will it take to train them before they are fully productive?

-

Peak Season – With a peak season that is usually 15 weeks or less, how will your system and operation perform to achieve the 2 to 4 times increase over the average daily volume? How much overtime, will be required?

-

Replenishment and Picking – Will your replenishment be able to keep up? Do you need to reslot, and at what cost? What SKUs are going to be your hot movers today, tomorrow? What to do with those SKUs having a sudden spike in volume?

-

Service Levels – If it continues to increase, how will your operation be able to satisfy customer’s increasing demand for shorter delivery windows at lower or no shipping costs? What new “value add” or personalization will be coming soon to your operation?

-

SKU and UoM Proliferation – How many more SKUs can your system take before it’s over capacity? Where will you locate them in the forward pick? What is this doing to your picking productivity? How will it affect your automation?

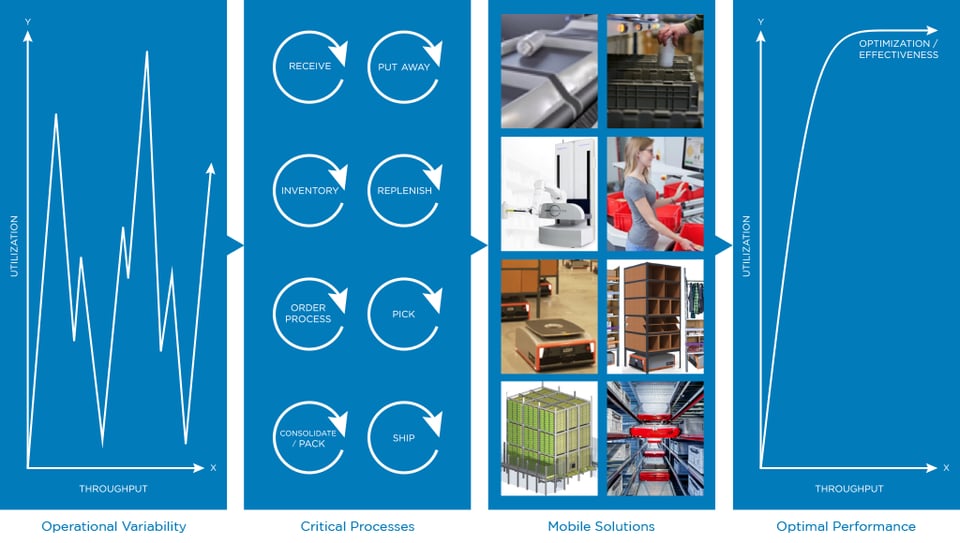

These things cause Ecommerce Fulfillment leaders so much headache. Why? As Deming described in “System of Profound Knowledge”, they create variation, instability, and are often beyond our control.

In other words, these top 4 challenges make it extremely difficult to manage the operation.

-

Volatility – they are likely to have dramatic and rapid swings or changes

-

Variability – they are inconsistent, often unpredictable, and disrupt the common practice

-

Uncertainty – they are unreliable, create unsureness, and cause processes to fluctuate

-

Complexity – they have related units, but the relationship among those units is imperfectly known

While fixed automation is primarily designed for speed and performs great under well-defined and consistent constraints, it often doesn't handle these four conditions well. However, mobile robotic subsystems offer a whole new way of thinking that will help you rest easier by combating these challenges with four words of their own.

-

Flexibility – Autonomous Mobile Robots such as Fetch Robotics that can operate in the forward picking field with operators offer the flexibility to augment a steady work staff. These AMR solutions can be applied in “meet me”, “follow me”, or “transport” modes which is important to understand, in order to achieve the desired benefits within the operation. Targeted at improving and/or reducing the operator’s travel time, which can often be as high as 65% of the overall pick time, these solutions are particularly valuable to manage a volatile labor market.

-

Scalability – The term “scalable solution” often means adding on to siloed islands of automation and scaling the fixed assets that surround them. While it sounds simple, it isn’t as easy as adding more blocks. It can be disruptive to the operation, involve surrounding integration, and have a potentially long project turnaround. Goods to Person robots such as GreyOrange have brought scalability to the “near term” as they can easily extend the volume, and throughput of the operation, by increasing the number of robots in the same field. Likewise, SKU growth and UoM expansion can be accommodated by extending the robot field and adding storage units or supplementing the field with a temporary manual pick area.

-

Elasticity – Order(s) to Picker or “meet me” robotic solutions such as Fetch Robotics, are elastic solutions that can easily be increased without changes in infrastructure for those hourly spikes to meet service commitments, as well as the extreme peak days whose volumes are multiples of the average. The “meet me” concept is similar in theory to the “pick and pass” solutions without the constraints common in conveyor-based zone route systems. Unlike fixed conveyance/automation, order-to-picker robotic systems have the unique ability to resume their original configuration after being stretched for peak so that outbound volumes can be increased without having to expand forward pick faces.

-

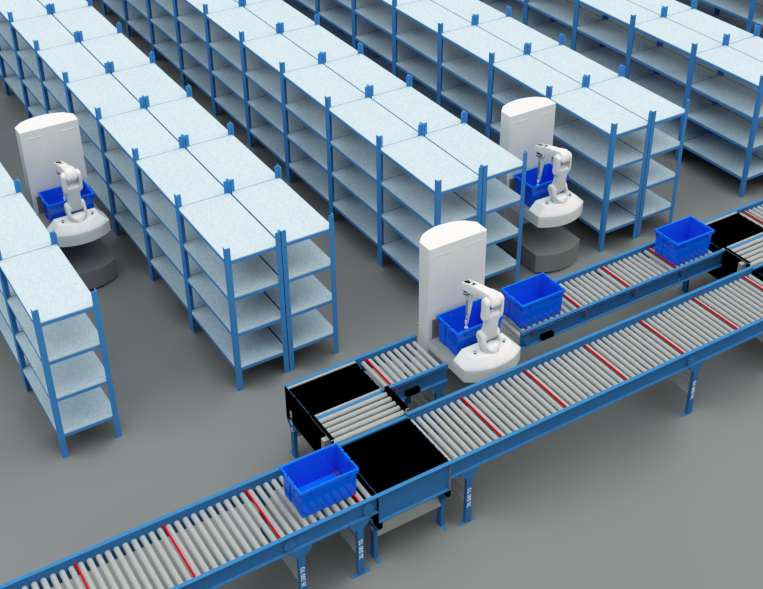

Agility – IAM Robotics has added another level to the playing field they call Autonomous Mobile Manipulation Robots (AMMR), the combination of a material handling arm with an autonomous mobile base that is designed to navigate the warehouse and picks orders directly from shelving. This level of automation provides dependability and flexibility during peak seasons. Whether it be parts distribution with extremely large SKU population and flat distribution of unit sales; the low-velocity SKUs within health & beauty, or the quality rigor required of certain ecommerce order fulfillment, automated robotic picking is where it’s at.

One of the most valuable benefits provided by these and other mobile robotic solutions is the ability to respond quickly and easily without operations having to “manage” through the vast exceptions that can occur in more traditional based solutions with fixed automation.

The key to incorporating and optimizing these solutions into a single harmonious solution is a Warehouse Execution System (WES) that can orchestrate the intricate parts across the entire system. Receiving to shipping, TREW’s SmartMoves-WX® WES organizes orders, workflow and assignments; coordinating people, process, automation and robotics to influence operational outcomes for the entire system.

Ecommerce fulfillment with its rampant acceleration pace and ravenous consumer demand, generates daunting operational complexity that leaves leaders with anxiety and panic “keeping us up at night”. Simplicity gives the ability to do the most with the least amount of effort providing us the most gratification, comfort, and confidence. So, it makes sense why we should look to simple solutions to solve our fulfillment operational challenges so we can rest easily and assured that our customers are getting their orders on time and in full.

Whether it be the robotic suppliers mentioned above or one of the many other very good mobile robotic solutions in the industry, they were all born out of the need to supply flexible, scalable, elastic, and agile solutions to ecommerce fulfillment operations across the globe facing the daily challenges of volatility, variability, uncertainty, and complexity.