7 Principles of a Winning Operational Team

Does Your Fulfillment Operation Compete Like A Champion?

Whether it is football, baseball, basketball, or soccer, when we usually think of champions - we think of sports. The well-planned strategies, team coordination, and well executed tactics are enjoyed and closely watched by millions. In 2020, we anxiously await the return of sporting events from little league to the big leagues. While it is possible that the 2020 basketball season may not resume, we can still draw upon some basic principles of the sport to provide us with a great analogy to see how well our fulfillment operation is putting points on the scoreboard when it counts the most to bottom-line performance.

The fundamental strategy of basketball is to produce scoring opportunities, with an offensive purpose of creating those opportunities and converting them into the maximum number of field goals. Again, very much like the operation within a fulfillment center.

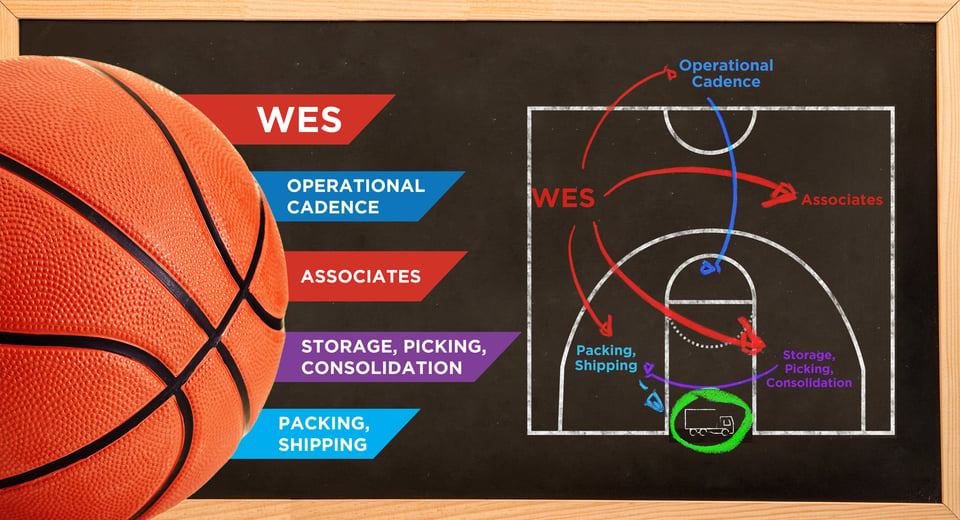

So if we think of our operation as a championship basketball team, here’s what it might look like.

-

Like a Point Guard, the operational cadence sets the pace by taking the throughput requirements and allocating mechanical and labor resources to achieve the goal each hour of every day as the ball is brought down court.

-

The Shooting Guard is quick to identify, fast acting, and uses the resources of the team to create opportunities, just like a well-trained team of associates.

-

Similar to that of a Small Forward, the WES (Warehouse Execution System) is versatile, aggressive in response timing, and has the agility to predict and react to constantly changing conditions.

-

The Power Forward has both the size and strength to own the midrange court. Likewise, the processes and automation for picking and consolidation are the capacity and throughput strengths within the middle of the fulfillment operation.

-

Packing and shipping, is the Center. The closest player to the goal. Taking tactical advantage of rebounds, and the plays set up by the other team members, they are the final touch before the order goes out the door.

This analogy doesn’t end with the players and their roles. Basketball and fulfillment operations share basic principles regarding “how” the team goes about their work. The seven principles below can be used by your team to reach throughput and customer service goals every day.

-

Set Up the Shot

As materials flow through the facility, it is important that each upstream process present materials in a manner that gives the best opportunity possible for the success of the downstream process. This could range from preparing replenished goods so that the pick can be performed fast and easily with one hand; to having enough work queue prior to an item sorter induction so that the operator doesn’t have gaps in available materials.

-

Balanced Scoring

In the game of basketball, balanced scoring is not about equal opportunity for shooting. It’s about using the skills and potential of every team member within their role to overwhelm the opponent with multiple threats that are harder to defend. Within most fulfillment centers, leaders have various mechanical and technology resources available to them. So, the challenge is to understand the operating variables that enable those resources, and how those resources and the right amount of staff work together to achieve optimal throughput out the door.

-

Well Executed Passing

Fulfillment takes a team, and just like basketball, a fulfillment team needs a good passing game. Three fundamental teaching points in passing a basketball are 1) keep your head up and be aware, 2) when passing, step toward the receiver, and 3) when catching, step toward the pass. Effective leaders in your facility want to know what is happening upstream and downstream of them. A leader responsible for a consolidation process will be in constant communication with the leader of picking so that they can adjust to evolving situations and work together to share resources and likewise with the leader of packing. If the packing area is running lean, consolidation needs to look at how they can turn orders faster or perhaps picking can release singles to provide packing with more work.

-

Keep the Ball Moving

A good basketball team will keep the ball moving to make it harder to defend as they look for an open lane to the goal. Sustaining material flow, is one of the most critical principles in any fulfillment operation. Yet surprisingly, too many operations don’t understand their particular material flow and how to optimize it. Without effective flow, processes and operator stations can get overwhelmed or starved, and neither condition is going to get orders shipped on time or within budget.

-

Get the Rebound

A rebound occurs when a player retrieves the ball following a missed field goal attempt. Exceptions in a fulfillment operation are just like that ball that hits the rim and bounces out. And like basketball, the most important thing about exceptions, beyond not making them, is to resolve and quickly turn them around so that throughput is not lost, and the customer is happy with their order. Too often, entire processes will be held up for exceptions that don’t get addressed and then they go to the exception graveyard where they can dwell for hours and sometimes days before they are resolved.

-

Control the Tempo of the Game

One of their responsibilities of a point guard is to control the pace of the game. In fulfillment, this is known as a well-communicated and calculated cadence where the volumes are broken down into meaningful durations of time with productivity-based staffing for each process. Each team member knows how much work to expect, when to expect it, and the resources they need to achieve it.

-

Know the Plays

Team athletes spend hours learning and memorizing plays because they can’t continuously stop mid-play to ask their teammates what to do next. The response must be automatic. Standard operating procedures in a fulfillment center is a must. And every area leader needs to understand the knobs and levers they have available to them so that they can create the optimal throughput given the order mix and complexity presented to them.

As a leader, take an opportunity to coach your team in these and other important operating principles so that they “bring their all to the court” rather than leaving it in the locker room.

“Push yourself to keep improving or you’ll stay as close to the bottom as you are to the top”

– John Wooden –