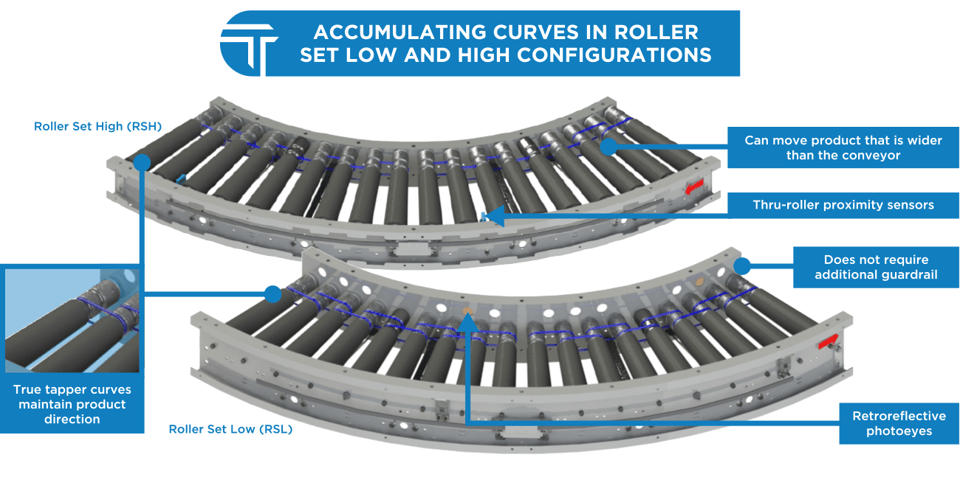

Product Spotlight - Series 1500 RSH & RSL Curves

Sometimes conveyor system layouts throw you a curve and you need flexibility in layout and operator conveyor interaction.

Trew’s Series 1500 MDR conveyor system has been updated to help you pick the right solution for your application whether it is accumulating flow or an area where operators interact with conveyed products.

Accumulating curves are now commercially available in 30, 45, 60, or 90-degree angles in both roller set low (RSL) and roller set high (RSH) configurations. All the curve configurations use the same top of support dimension and integrate seamlessly with the rest of the conveyor platform.

When do you use RSH vs. RSL?

Rollers Set High conveyor (RSH) - Accumulating Flow

|

Rollers Set Low conveyor (RSL) - Operator Interaction

|

When to use RSH?

|

When to use RSL?

|

The curve modules are part of the Series 1500 MDR product line which is often used in distribution for tote and case handling applications. The product line is highly versatile, easily configured, and pre-wired so it’s ready for installation.